Retro, Reinvented: The Unique Process Behind Hirali Textiles

As throwback looks find new popularity across Japan, dyeing company Takeno Senko Ltd. leverages a one-of-a-kind manufacturing process to create eye-catching textiles that pay homage to retro styles in entirely modern ways. Below, we look at what sets the company’s distinctive Hirali towels, scarves, and tenugui (a type of all-purpose cloth popular in Japan) apart from all the rest.

From the

Heartland of Japan

How Senshu cotton makes its way into Hirali textiles

Legend has it that the cotton grown today in Senshu, Osaka, can trace its roots back more than a millennium to Japan’s Heian Period. Supposedly, a cottonseed was brought back to the country from China by Kūkai, a famous monk and founder of the Shingon school of Buddhism, during the Tang dynasty. This humble seed, and the cotton it produced, revolutionized the Japanese textile industry over the following centuries.

As technology advanced, new methods were developed to improve the quality of the cloth produced from this cotton, including the bleaching process that was developed in Sakai City - now known as the “Town of Tenugui” - about 350 years ago.

Tenugui are purposefully left unhemmed to facilitate quicker drying. Shown: Hirali Tenugui, Faraway Hanabi

Shown: Hirali Kitchen Towel, Shining Wind

The city’s location directly between the cotton fields of Senshu and the marketplaces of Osaka made it the perfect location for the region’s nascent bleaching industry, though there were a few other geographical advantages at play: the Ishizu River, which runs through the area, provided the plentiful water required for bleaching large amounts of cloth, and the open plains allowed ample sunlight for drying.

The result of this centuries-old process is called wazarashi - the term used for cotton cloth that has been bleached to remove any starch or impurities - and it is this supple material that serves as the foundation for our Hirali towels, tenugui, and stoles.

Dyeing for More

Why Takeno Senko created their unique dyeing process

Though the pedigree behind Takeno Senko’s cotton cloth base is impressive, it is the method used to dye the material that has created a truly unique product.

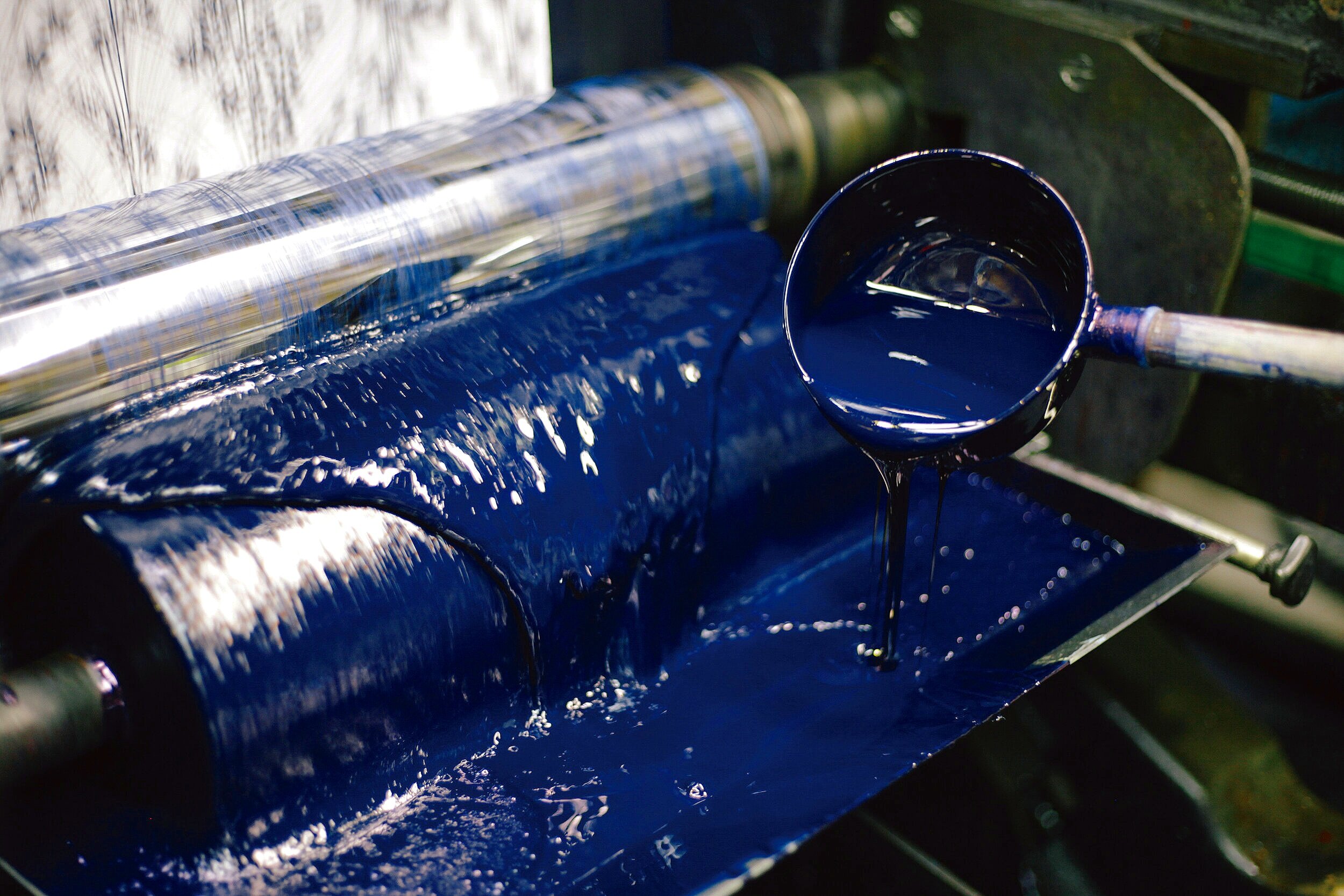

A machine used to dye textiles applies a pattern to fabric at a Takeno Senko facility.

Most textiles, including those made from wazarashi, are colored by soaking all or part of the cloth with dye, altering both sides simultaneously. An example of this is Japan’s chusen dyeing technique, in which part of the cloth is covered with glue to preserve its natural color while dye is pulled through the rest of the material with a vacuum pump.

The dyeing experts at Takeno Senko envisioned something a little different, however. Their goal was to add separate colors to each side of the fabric in a double-sided design that effectively layered the different hues on top of one another to create a mixture of both - an idea inspired by thousand-year-old fashion concept kasane no irome, which involved layering kimono to create specific color combinations and which was commonly practiced among the upper echelons of Japan’s Heian Period.

The double-sided designs of Hirali textiles are demonstrated in the Hirali Tenugui, Honeycomb (top) and Hirali Tenugui, Tortoise Shell.

Shown: Hirali Cotton Gauze Stole, Resting Rain (left); Hirali Cotton Gauze Stole, Sleeping Mountain

To achieve this effect - one that no other company has managed to produce - Takeno Senko artisan Eiji Kakuno developed a whole new method of dyeing cotton cloth, one that uses a variation on engraved roll printing to impart bold colors and detailed designs to thin cotton textiles, one side at a time, with no bleed-through. When applied to high-quality cotton fabric, the result is the look for which Hirali (a name derived from the Japanese word for “flutter”) is known.

Dyeing artisan Eiji Kakuno works on a part at the Takeno Senko facility in Sakai City.

Pioneers of Printing

What makes Takeno Senko’s printing methods so different

In traditional roll printing, a design is carved into a cylindrical printing plate, which is then used to apply dye to the surface of a piece of fabric. In developing the proprietary technique used to create the Hirali line, Takeno Senko introduced a number of improvements to this system, many of which are unknown outside the walls of the company’s facility in Sakai City.

Two workers operate a machine used to print patterns on Takeno Senko textiles.

One difference that is evident is the way the dye interacts with the fibers of Hirali textiles; instead of sitting on the surface of their towels and tenugui (limiting water absorption in the process), the dye actually soaks into the fibers, changing the color of the fabric while allowing it to retain its remarkable absorbency.

Exactly how Takeno Senko manages to apply dye that soaks into their textiles but not through them is a mystery to all but a select few craftsmen. What we can say for certain, however, is that we’re glad they managed to crack the problem and create these functional works of art for all to enjoy.

A Hirali cotton gauze stole featuring the Snowy Hail design